Journal of Intelligent Agricultural Mechanization ›› 2024, Vol. 5 ›› Issue (1): 1-11.DOI: 10.12398/j.issn.2096-7217.2024.01.001

LI Guichuan( ), LI Haiyu, YANG Shaopeng, HUANG Yuxiang, GAO Xiaojun, FU Zuoli(

), LI Haiyu, YANG Shaopeng, HUANG Yuxiang, GAO Xiaojun, FU Zuoli( )

)

Received:2023-11-20

Revised:2023-12-25

Online:2024-02-15

Published:2024-02-07

Corresponding author:

FU Zuoli

About author:LI Guichuan, Postgraduate; research interests: modern agricultural technology and equipment. E-mail: lgchuan@nwsuaf.edu.cn

Supported by:CLC Number:

LI Guichuan, LI Haiyu, YANG Shaopeng, HUANG Yuxiang, GAO Xiaojun, FU Zuoli. Simulation and experiment of distributors of different outlet types of pneumatic collection and discharging systems based on CFD-DEM coupling[J]. Journal of Intelligent Agricultural Mechanization, 2024, 5(1): 1-11.

Add to citation manager EndNote|Ris|BibTeX

URL: http://znhnyzbxb.niam.com.cn/EN/10.12398/j.issn.2096-7217.2024.01.001

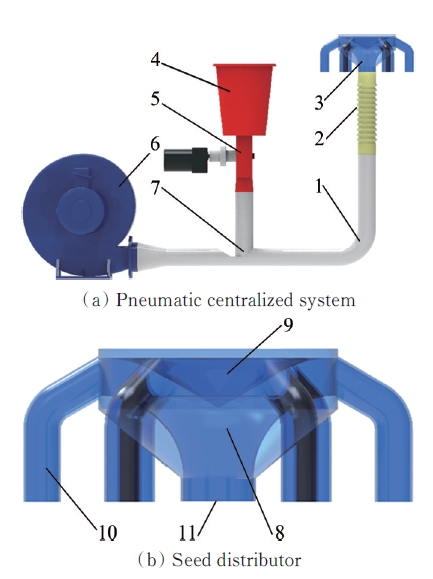

Figure 1 Structure of the pneumatic centralized system and seed distributor1. Seed tube 2. Corrugated pipe 3. Seed distributor 4. Seed box 5. Seed metering 6. Fan 7. Air-seed mixer 8. Inner tube 9. Conical cover 10. Outlet 11. Inlet

| Item | Details | Index | Value | |

|---|---|---|---|---|

| CFD | Materials | Fluid/air | Density/(kg·m-3) | 1.225 |

| Viscosity/(kg·m-1·s-1) | 1.789×10-5 | |||

| Boundary conditions | Solid/PLA | Density/(kg·m-3) | 1 250 | |

| Velocity-inlet | Velocity magnitude/(m·s-1) | 28 | ||

| Turbulence | Turbulence intensity/% | 4 | ||

| Hydraulic diameter/mm | 50 | |||

| Flow-outlet | Outlet type | Flow-outlet | ||

| Wall | Wall motion | Stationary wall | ||

| Shear condition | No slip | |||

| DEM | Materials (wheat seeds) | Particle | overall dimensions/mm | 7.01×3.47×3.20 |

| Thousand-grain weight/g | 48.96 | |||

| Water content/% | 10.80 | |||

| Poisson’s ratio | 0.41 | |||

| Shear modulus/Pa | 4.79×107 | |||

| Density/(kg·m-3) | 1 350 | |||

| wall | Poisson’s ratio | 0.35 | ||

| Shear modulus/Pa | 1.3×109 | |||

| Density/(kg·m-3) | 1 250 | |||

| Interaction | Particle-particle | Coefficient of restitution | 0.47 | |

| Coefficient of static friction | 0.55 | |||

| Coefficient of rolling friction | 0.28 | |||

| Interaction contact model | Hertz-Mindlin | |||

| Particle-wall | Coefficient of restitution | 0.50 | ||

| Coefficient of static friction | 0.22 | |||

| Coefficient of rolling friction | 0.16 | |||

| Interaction contact model | Hertz-Mindlin | |||

| Particle | Particle generation | Particle radius/(mm×mm×mm) | 7.00×3.20×3.20 | |

| Factory type | Dynamic/unlimited number | |||

| Generation rate/(s-1) | 2 000 |

Table 1 CFD-DEM simulation calculation parameters

| Item | Details | Index | Value | |

|---|---|---|---|---|

| CFD | Materials | Fluid/air | Density/(kg·m-3) | 1.225 |

| Viscosity/(kg·m-1·s-1) | 1.789×10-5 | |||

| Boundary conditions | Solid/PLA | Density/(kg·m-3) | 1 250 | |

| Velocity-inlet | Velocity magnitude/(m·s-1) | 28 | ||

| Turbulence | Turbulence intensity/% | 4 | ||

| Hydraulic diameter/mm | 50 | |||

| Flow-outlet | Outlet type | Flow-outlet | ||

| Wall | Wall motion | Stationary wall | ||

| Shear condition | No slip | |||

| DEM | Materials (wheat seeds) | Particle | overall dimensions/mm | 7.01×3.47×3.20 |

| Thousand-grain weight/g | 48.96 | |||

| Water content/% | 10.80 | |||

| Poisson’s ratio | 0.41 | |||

| Shear modulus/Pa | 4.79×107 | |||

| Density/(kg·m-3) | 1 350 | |||

| wall | Poisson’s ratio | 0.35 | ||

| Shear modulus/Pa | 1.3×109 | |||

| Density/(kg·m-3) | 1 250 | |||

| Interaction | Particle-particle | Coefficient of restitution | 0.47 | |

| Coefficient of static friction | 0.55 | |||

| Coefficient of rolling friction | 0.28 | |||

| Interaction contact model | Hertz-Mindlin | |||

| Particle-wall | Coefficient of restitution | 0.50 | ||

| Coefficient of static friction | 0.22 | |||

| Coefficient of rolling friction | 0.16 | |||

| Interaction contact model | Hertz-Mindlin | |||

| Particle | Particle generation | Particle radius/(mm×mm×mm) | 7.00×3.20×3.20 | |

| Factory type | Dynamic/unlimited number | |||

| Generation rate/(s-1) | 2 000 |

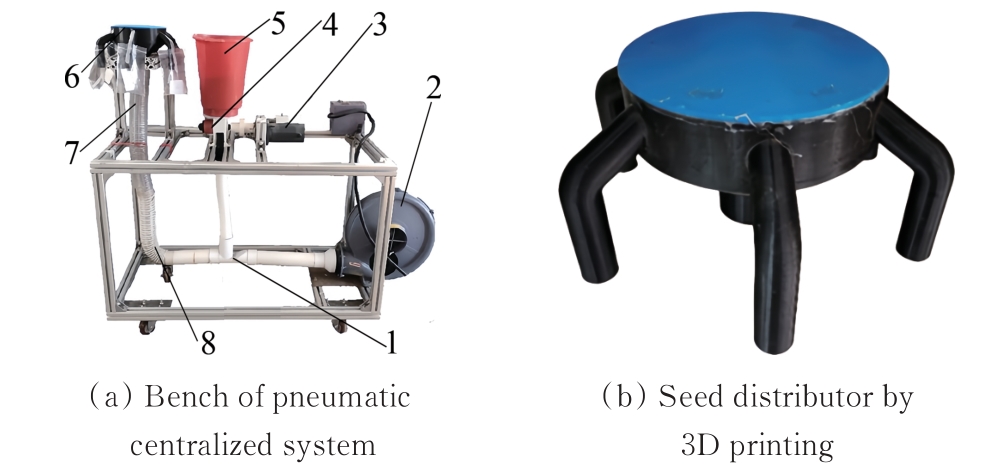

Figure 6 Device for the bench experiment1. Mixer 2. Speed regulating fan 3. Speed regulating motor 4. Outer groove wheel seed metering device 5. Seedbox 6. Seed distributor 7. Corrugate pipe 8. Gas seed conveying pipeline

| Type of distribution | Y-type | T-type | M-type |

|---|---|---|---|

| The coefficient of variation/% | 10.95 | 14.64 | 7.23 |

Table 2 The simulation results of three types of distributors

| Type of distribution | Y-type | T-type | M-type |

|---|---|---|---|

| The coefficient of variation/% | 10.95 | 14.64 | 7.23 |

| Factors | Level |

|---|---|

| The inclination of outlet pipe θ1/(°) | 50, 55, 60, 65, 70 |

| The cone angle of the top cover θ2/(°) | 100, 120, 140, 160, 180 |

| The inlet diameter Dr/mm | 56, 58, 60, 62, 64 |

| The fillet radius R/mm | 62, 66, 70, 74, 78 |

The pneumatic conveying speed Vc/(m·s-1) | 28, 30, 32, 34, 36 |

Table 3 Factor level table

| Factors | Level |

|---|---|

| The inclination of outlet pipe θ1/(°) | 50, 55, 60, 65, 70 |

| The cone angle of the top cover θ2/(°) | 100, 120, 140, 160, 180 |

| The inlet diameter Dr/mm | 56, 58, 60, 62, 64 |

| The fillet radius R/mm | 62, 66, 70, 74, 78 |

The pneumatic conveying speed Vc/(m·s-1) | 28, 30, 32, 34, 36 |

| Level | The inclination angle θ1/(°) | The cone angle θ2/(°) | The fillet radius R/mm |

|---|---|---|---|

| -1 | 55 | 100 | 66 |

| 0 | 60 | 120 | 70 |

| 1 | 65 | 140 | 74 |

Table 4 The factor level table of the multi-factor orthogonal experiment

| Level | The inclination angle θ1/(°) | The cone angle θ2/(°) | The fillet radius R/mm |

|---|---|---|---|

| -1 | 55 | 100 | 66 |

| 0 | 60 | 120 | 70 |

| 1 | 65 | 140 | 74 |

| Index | Calculated result | Simulation experiment | Bench experiment | Field experiment |

|---|---|---|---|---|

The value of coefficient/% | 6.05 | 6.03 | 7.03 | 7.58 |

Table 5 Verification result of M-type seed distributor

| Index | Calculated result | Simulation experiment | Bench experiment | Field experiment |

|---|---|---|---|---|

The value of coefficient/% | 6.05 | 6.03 | 7.03 | 7.58 |

| 1 | ABDOLAHZARE Z, MEHDIZADEH S A. Real time laboratory and field monitoring of the effect of the operational parameters on seed falling speed and trajectory of pneumatic planter [J]. Computers and Electronics in Agriculture, 2018, 145: 187-198. |

| 2 | DONG J X, GAO X J, ZHANG S L, et al. Design and test of the maize posture control and driving precision metering device for high-speed seeder [J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(11): 108-119. |

| 3 | GUO J, YANG Y, MUHAMMAD S M, et al. Design and simulation for seeding performance of high-speed inclined corn metering device based on discrete element method (DEM) [J]. Scientific Reports, 2022. |

| 4 | YATSKUL A, LEMIERE J P. Establishing the conveying parameters required for the air-seeders [J]. Biosystems Engineering, 2018, 166: 1-12. |

| 5 | LEI X, HU H, YANG W, et al. Seeding performance of air-assisted centralized seed-metering device for rapeseed [J]. International Journal of Agricultural and Biological Engineering, 2021, 14(5): 79-87. |

| 6 | LEI X L, LIAO Y T, LIAO Q X. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat [J]. Computers and Electronics in Agriculture, 2016, 131: 29-39. |

| 7 | LIAO Y T, WANG L, LIAO Q X. Design and test of an inside-filling pneumatic precision centralized seed-metering device for rapeseed [J]. International Journal of Agricultural and Biological Engineering, 2017, 10(2): 56-62. |

| 8 | ZHANG X H, WANG Y Z, ZHANG L, et al. Design and experiment of wheat pneumatic centralized seeding distributing system [J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(3): 59-67. |

| 9 | ZHAO J H, LIU L J, YANG X J, et al. Design and experiment of pneumatic seeding system of teff seeder [J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(S1): 101-107. |

| 10 | XING H, ZANG Y, WANG Z M, et al. Design and parameter optimization of rice pneumatic seeding metering device with adjustable seeding rate [J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(4): 20-28. |

| 11 | DAI Y Z, LUO X W, ZHANG M H, et al. Design and experiments of the key components for centralized pneumatic rice dry direct seeding machine [J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(10): 1-8. |

| 12 | LEI X L, LIAO Y T, CONG J L, et al. Parameter optimization and experiment of air-assisted centralized seed-metering device of direct seeding machine for rape and wheat [J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 34(12): 16-26. |

| 13 | MA W P, YOU Y, WANG D C, et al. Optimal design and experiment of pneumatic and pneumatic collecting and discharging system of alfalfa cut-root reseeding and fertilizer applicator [J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(9): 70-78. |

| 14 | KUMAR V J F, DURAIRAJ C D. Influence of head geometry on the distributive performance of air-assisted seed drills [J]. Journal of Agricultural Engineering Research, 2000, 75(1): 81-95. |

| 15 | LI Z H, WANG D C, LIU G L, et al. CFD simulation and improvement of air-stream distributive metering device [J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(3): 64-68. |

| 16 | WANG Y, WILLIAMS K, JONES M, et al. CFD simulation methodology for gas-solid flow in bypass pneumatic conveying-A review [J]. Applied Thermal Engineering, 2017, 125: 185-208. |

| 17 | GUO F, LI X W, FAN C M, et al. Flow field characteristics of pneumatic conveying system in air seeder: A review [J]. Journal of Agricultural Mechanization Research, 2021, 43(2): 1-9, 15. |

| 18 | KLINZING G E. A review of pneumatic conveying status, advances and projections [J]. Powder Technology, 2018, 333: 78-90. |

| 19 | GAO X J, ZHOU Z Y, XU Y, et al. Numerical simulation of particle motion characteristics in quantitative seed feeding system [J]. Powder Technology, 2020, 367: 643-658. |

| 20 | MUDARISOV S, BADRETDINOV I, RAKHIMOV Z, et al. Numerical simulation of two-phase "air-seed" flow in the distribution system of the grain seeder [J]. Computers and Electronics in Agriculture, 2020, 168: 105151. |

| 21 | KIECKHEFEN P, PIETSCH S, DOSTA M, et al. Possibilities and limits of computational fluid dynamics-discrete element method simulations in process engineering: a review of recent advancements and future trends [J]. Annual Review of Chemical and Biomolecular Engineering, 2020, 11: 397-422. |

| 22 | HU H J, ZHOU Z L, WU W C, et al. Distribution characteristics and parameter optimization of an air-assisted centralized seed-metering device for rapeseed using a CFD-DEM coupled simulation [J]. Biosystems Engineering, 2021, 208: 246-259. |

| 23 | WANG L, LIAO Y T, WAN X Y, et al. Design and test on distributor device of air-assisted centralized metering device for rapeseed and wheat [J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(4): 43-53. |

| 24 | KONG X R, LIU J, YANG T Y, et al. Numerical simulation of feed pellet breakage in pneumatic conveying [J]. Biosystems Engineering, 2022, 218: 31-42. |

| 25 | LI H B, LI H, QI X D, et al. Simulation and parameter optimization of seed metering device based on CFD-DEM [J]. Journal of Intelligent Agricultural Mechanization, 2021, 2(2): 26-41. |

| 26 | YANG L, XIE Y H. Pneumatic conveying engineering [M]. Beijing: Mechanical Industry Press, 2006. |

| 27 | TRIPATHI N M, SANTO N, KALMAN H, et al. Experimental analysis of particle velocity and acceleration in vertical dilute phase pneumatic conveying [J]. Powder Technology, 2018(330): 239-251. |

| 28 | LI G C, LI H Y, LI X, et al. Establishment and calibration of discrete element model for buckwheat seed based on static and dynamic verification test [J]. Agriculture, 2023, 13: 1024. |

| 29 | , Testing methods of sowing in lines [S]. |

| [1] | GAO Zhen, LU Caiyun, LI Hongwen, HE Jin, WANG Qingjie, GUO Zhaoyang. Research progress and the prospect of crucial technology of seed spacing information detection based on computer vision [J]. Journal of Intelligent Agricultural Mechanization, 2023, 4(3): 50-60. |

| [2] | LI Qianxi, SUN Xiaoming, JIANG Hanhui, WU Airu, FU Longsheng, LI Rui. Design and test of intelligent spraying unmanned vehicle for greenhouse tomato based on YOLOv4-tiny [J]. Journal of Intelligent Agricultural Mechanization, 2023, 4(2): 44-52. |

| [3] | Ji Yao, Hu Shuangyan, Yan Wei, Zhang Wenyi. Structure design and experiment of air suction double-layer cylinder seedlingraising and sowingline [J]. Journal of Intelligent Agricultural Mechanization (in Chinese and English), 2022, 3(1): 46-53. |

| [4] | Mei Song, Xiao Suwei, Jiang Qinghai, Lü Xiaolan, Tong Yifei. Design and experiment ofself-propelled precisionsowing and fertilizing control system for vegetables [J]. Journal of Intelligent Agricultural Mechanization (in Chinese and English), 2022, 3(1): 54-61. |

| [5] | Bohong Li, , , Hua Li, Xindan Qi, Xi Chen, , Yunlong Ma, Yongjian Wang. Simulation and parameter optimization of seed metering device based on CFDDEMSimulation and parameter optimization of seed #br# metering device based on CFDDE#br# [J]. Journal of Intelligent Agricultural Mechanization (in Chinese and English), 2021, 2(2): 26-41. |

| [6] | Zhaoyan You, Ya Gao, Huichang Wu, Xuemei Gao, Jianchun Yan, Huanxiong Xie. Development and test of 2BFLA-200 type multivariety green manure intelligent mixerDevelopment and test of 2BFLA-200 type #br# multivariety green manure intelligent mixer#br# [J]. Journal of Intelligent Agricultural Mechanization (in Chinese and English), 2021, 2(2): 42-50. |

| [7] | Deping Song, Cheng Wang, Dongxia Sun, Kaikai Liu, Aimin Zhang. Design and test of intelligent cotton planter based on Beidou navigation* [J]. Journal of Intelligent Agricultural Mechanization (in Chinese and English), 2021, 2(1): 44-50. |

| [8] | Haojun Wen, Xuegeng Chen, Fochu Pan. Development of precision seeder for drip irrigation under plastic film in Xinjiang [J]. Journal of Intelligent Agricultural Mechanization (in Chinese and English), 2020, 1(1): 7-12. |

| [9] | Sun Yitian, Chen Gang, Li Qinglong, Sun Yongjia, Shen Jingxin, Yan Ning. Application and development trend of intelligent agriculture [J]. Journal of Intelligent Agricultural Mechanization (in Chinese and English), 2020, 1(1): 56-59. |

| [10] | You Zhaoyan, Gao Xuemei, Xu Hongbo, Wu Huichang, Yan Jianchun, Cao Mingzhu. Design and experiment of intelligent green manure spreading device based on MAV [J]. Journal of Intelligent Agricultural Mechanization (in Chinese and English), 2020, 1(1): 60-67. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||